Service

- Sheet Metal Fabrication

- Laser Cutting

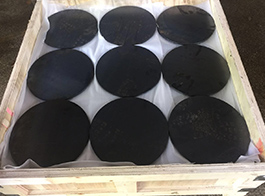

- Flame & Plasma Cutting

- Waterjet Cutting

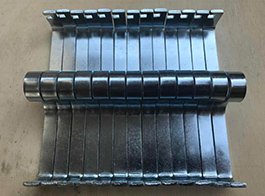

- Metal Stamping

- Sheet Metal Bending

- Sheet Metal Rolling

- Sheet Metal Roll Forming

- Metal Tube Fabrication

- Tube Saw Cutting

- Laser Tube Cutting

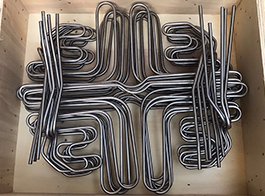

- Tube Bending

- Tube Coiling

- Tube End Forming

- Profile Bending

- Welding and Fabrication

- Sheet Metal Welding Fabrication

- Tube Welding Fabrication

- Steel Structure Fabrication

- Surface Finishing

- Products Assembly

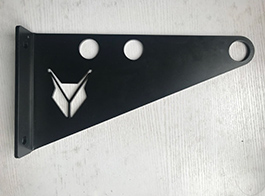

Sheet Metal Fabrication and Powder Coating for Playground Steel Clamps

Products Name: Playground Steel Clamps

Function: Playground Equipment Parts

Manufacturing Process: Steel Sheet Laser Cutting, Tube Saw Cutting, Bending, Hole Drilling, Welding and Powder Coating

Materials: Q235 Steel Sheet and Q235B Seamless Steel Pipe

Thickness: 5mm Sheet, 6mm Tube with 57mm Outer Diameter

Accessories: M16*1.5 Screw

Surface Finishing: Deburring, Polishing and Powder Coating

Packaging: Plastic Bag, Plastic Bubble Film, Wooden Box

Lead Time: 45 Days

More Project Cases

As a professional manufacturer of metal fabrication in China, we offer one-stop solution for sheet metal manufacturing, tube fabrication and steel structure fabrication. The mainly service including metal cutting (saw, laser, flame, plasma and waterject cutting), metal bending (sheet folding, tube/rod/section bending, tube coiling), metal stamping, deep drawing, CNC punching, welding (SMAW, GTAW, GMAW, TIG, MIG/MAG), surface finishing (mirror polished, brushed finishing, powder coating, anodizing, zinc plating, hot dip galvanized, chrome plating and nickel plating), assembly and packaging. We manage your project from materials, manufacturing, inspection, packaging to delivery. Here listed some of the projects we have produced for your reference. Maybe they can help you with your upcoming project.

We also provide others value-added services, such as design for manufacturability, technology support, quick-turn prototyping, machining and tooling make in-house and more. If you are looking for a real factory to work the steel clamps fabrication job, Maxtech will be your ideal partner.