Service

- Sheet Metal Fabrication

- Laser Cutting

- Flame & Plasma Cutting

- Waterjet Cutting

- Metal Stamping

- Sheet Metal Bending

- Sheet Metal Rolling

- Sheet Metal Roll Forming

- Metal Tube Fabrication

- Tube Saw Cutting

- Laser Tube Cutting

- Tube Bending

- Tube Coiling

- Tube End Forming

- Profile Bending

- Welding and Fabrication

- Sheet Metal Welding Fabrication

- Tube Welding Fabrication

- Steel Structure Fabrication

- Surface Finishing

- Products Assembly

Sheet Metal Laser Cutting

Laser cutting in metal fabrication industry is applied for different kinds of materials where complex contours demand precise, fast and force-free processing. Lasers create narrow kerfs and thus achieve high-precision cuts. Laser cutting will not cause any distortion and mostly speaking, post-processing is unnecessary as the component is subject to only little heat input and can mostly be cut dross-free.

Laser cutting has lots of advantages over mechanical cutting, like easier workholding and reduced contamination of workpiece (since there is no cutting edge which can become contaminated by the material or contaminate the material). Precision will be much better because the laser beam does not wear during the process. And the the chance of warping the material that is being cut will be dramatically reduced, since laser system have a small heat-affected zone. Also, some materials are very difficult or impossible to cut by more traditional means.

Clean cut edges without burr or dust formation, fine contours cutting, cost-efficient for small-batch production are all benefits of laser cutting. Compared with plasma cutting, laser cutting also has lots of advantages, being more precise and using less energy when cutting sheet metal. Contact us now for more information or require a custom quote.

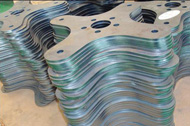

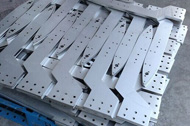

Steel Parts

Stainless Steel Parts

Aluminum and Copper Parts

Maximum Cutting Thickness for Different Materials:

Carbon Steel Sheet/Mild Steel Sheet: ≤20mm

Stailness Steel Sheet: ≤12mm

Aluminum Sheet: ≤6mm

Copper Sheet: ≤3mm

In addition to laser cutting service, we can also provide saw cutting, flame cutting, plasma cutting, water jet cutting, metal stamping and CNC punching service according to your requirements.

The other value-added service as follows:

1. Hole Drilling, Grinding, Machining, Riveting

2. Metal Sheet Rolling, Bending and Folding for Press Brake

3. Welding Service: SMAW, GTAW, GMAW, TIG, MIG/MAG

4. Heat Treatment

5. Surface Finishing

(1) Buffing and Polishing (Metal Mirror Polished, Brushed Metal Finishing)

(2) Sandblasting, Pickling and Phosphating

(3) Powder Coating, Anodizing, Zinc Plating, Hot Dip Galvanized, Chrome Plating and Nickel Plating

(4) Assembly

If you are looking for a Chinese laser cutting factory, Maxtech will be your ideal partner. We manufacturing burr-free and strict tolerances metal parts by shear, sawing, plasma cutting, laser cutting, waterjet cutting, metal stamping and CNC punching. And we have 15 years of experience in custom metal cutting, metal polishing, precision machining and surface treatment metal parts. Our experience and manufacturing capabilities provide the skills and capacity to meet the various needs of customers. All these and more are the requirements we achieve every day for products shipped worldwide.

We provide the processing method of metal cutting with shear and cutting without shear according to your requirement. Usually we determine the final production process according to the material, order quantity, tolerance, products size and flatness request. For example, more than 6mm aluminum sheet and 3mm the copper sheet can be not suitable for laser cutting. The stamping process have a pre-period mold cost, so it's suitable for bulk and stable orders. The water cutting have a low cutting efficiency, so it is not suitable for delivery urgent orders. Contact us today to require a custom quote on any project you may have. Fair and competitive prices are always available.